Dynamic thermal scenarios call for accurate, transient software solutions.

Critical Temperature Analysis

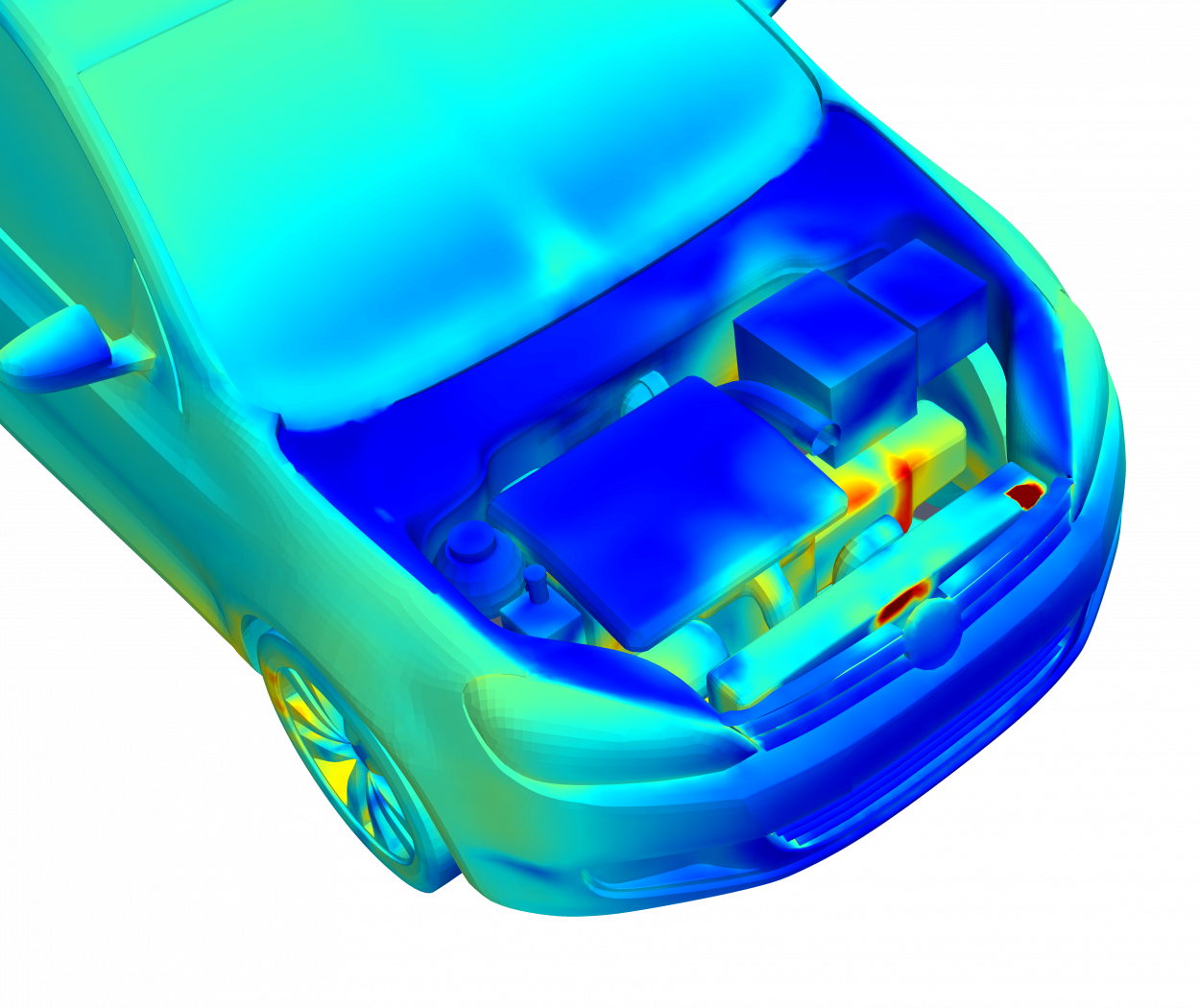

One of the most critical temperature analyses for an automotive thermal engineer is how to manage thermal transients during a “key-off” or “hot soak” scenario. After the vehicle is in motion for some time, whether on the highway or driving in the city, a hot soak begins when the driver turns off the engine.

When the engine is turned off, there is no longer forced convection to cool the engine compartment or underbody components. This event causes a temperature spike in the engine compartment and underbody because the parts are hot from the vehicle’s operation. This temperature spike can last several minutes.

Design Temperatures for Durability

Engineers must identify if the components exceed their max temperature target. When the fan is running to help cool off components, parts with less mass cool down quickly; however, high mass parts, such as DPFs or catalysts, release the heat slowly. This effect, combined with a lack of convection, causes temperatures to rise initially and then cool down over time. Due to components with a high mass in the vehicle, the cooling-off period is critical since it can impact long term component durability.

Vehicle components can become so hot that they can potentially fail or degrade other nearby parts, leading to severe safety, durability, or warranty issues. Plastic components are being used more frequently to save on cost and weight but are more sensitive to temperature. Engineers must carefully analyze component placement and thermal shielding to avoid costly late-stage design fixes or, worse, failures.

Design Verification with Real-World Evaluations

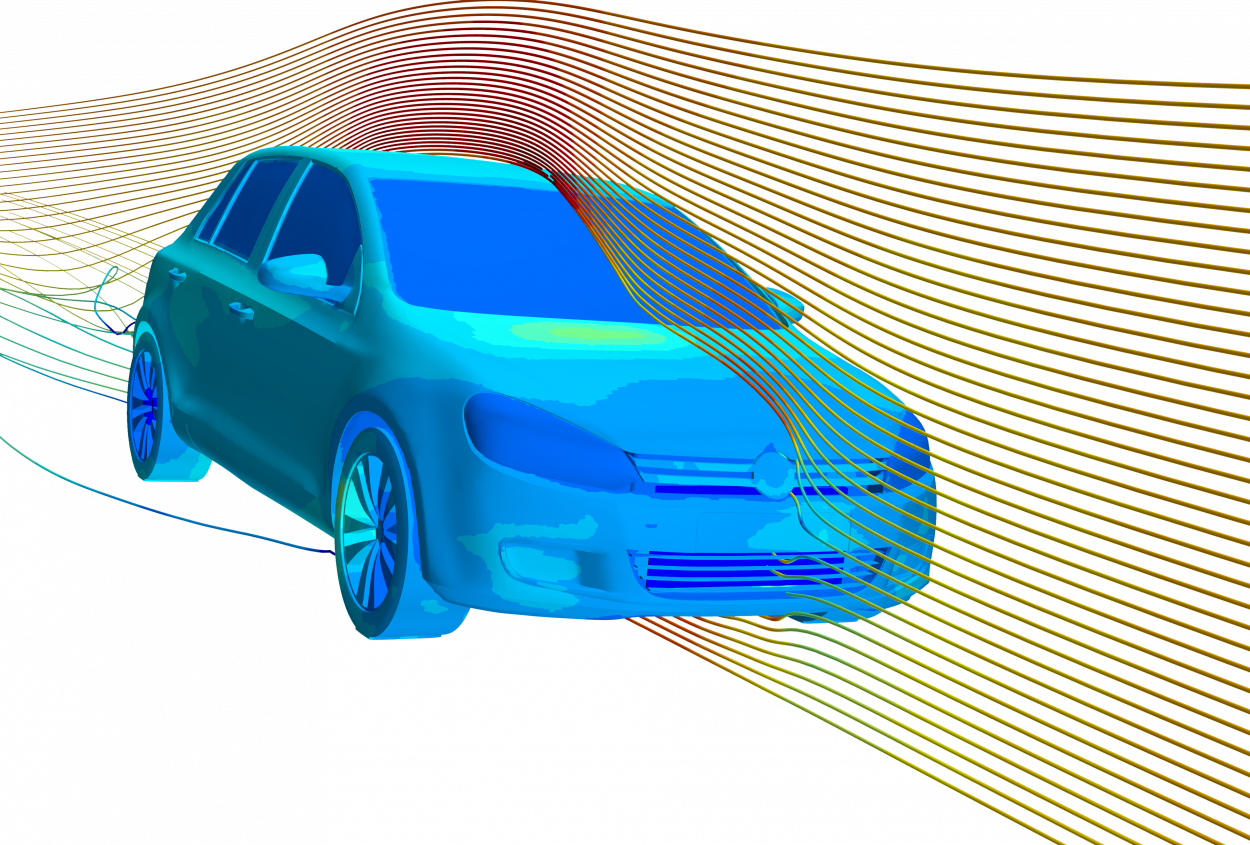

Simulating how a customer will operate the car will lead to less testing, a faster turnaround time for design verification, and evaluations. Only a transient analysis will allow engineers to simulate the real-world use of a vehicle. To fit the necessary analyses into an OEM production timeline requires an advanced simulation methodology to capture the fundamental physics.

In addition to our advanced thermal simulation software, TAITherm, we offer a turn-key simulation process using CoTherm. This adaptable solution supports all your transient simulation needs, with more efficient HPC resource allocation and shorter simulation times.

Strategize Your Thermal Management

Our team can provide insight into a proper thermal management strategy for your exhaust or underhood design. Let's talk and discuss a custom solution for your thermal management problems.

You Might Also Be Interested In:

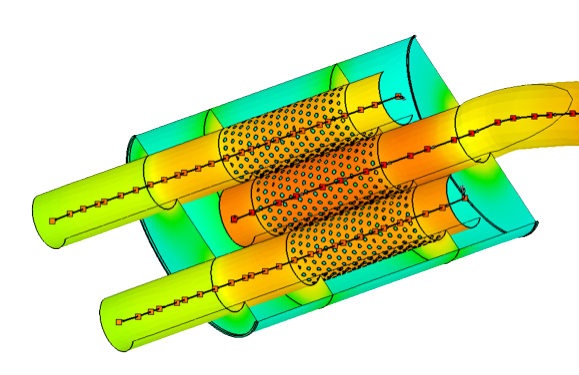

Improved Heat Protection Strategies

The Exhaust Extension uses transient thermal simulation to solve thermal challenges in one of a vehicle's most complex systems: the exhaust system. With a library of pre-built components and a simple set-up process, you can optimize your exhaust system design quickly and understand how it will perform in hot soak or time-based scenarios. The Exhaust Extension is built to reduce set-up time, generate results quickly, and provide realistic solutions with transient simulation.

Manage Complex Thermal Challenges

Our team utilizes advanced simulation tools to provide you with fast and accurate data and simulations for transient or steady-state cases for real-world scenarios. We use TAIThermTM in conjunction with our Exhaust Extension to quickly create an underbody/exhaust or underhood model that considers the unique physics the components undergo in cases including hill climbs, trailer towing, hot soaks, or driving cycles. Our method utilizes all modes of heat transfer, so you never miss a thermal interaction.

Our custom CAE coupling process allows you to utilize the strengths of multiple simulation tools for better accuracy and in-depth representation of your design problems. Our team is well-versed in TAITherm, our transient thermal simulation tool, and many other popular CAE tools. Resolve your thermal problems quickly and get more time back for optimization when you have us run coupled simulations for you.

Getting Started

Let's talk

If you would like to learn more about our key-off/hot soak modeling methods and how it can provide you with an actionable design direction, please reach out! We will demonstrate how our software will fit your specific requirements and help you save time and costs where it counts.

Support

We are here to work with you at every step. We support our customers throughout your service project with excellent communication; we are only a phone call or email away. Our commitment to you never changes.